Industrial IoT for energy efficiency and process optimization

In a so rapidly changing world, we have to keep up with the times, making our company more connected, efficient and productive, in line with the industry 4.0 paradigms.

Tera, specialized in IoT technologies and related services, offers customized solutions to optimize production processes in every industrial sector, from metallurgical to agricultural, from logistics to automotive.

IoT systems to save energy and optimize performance

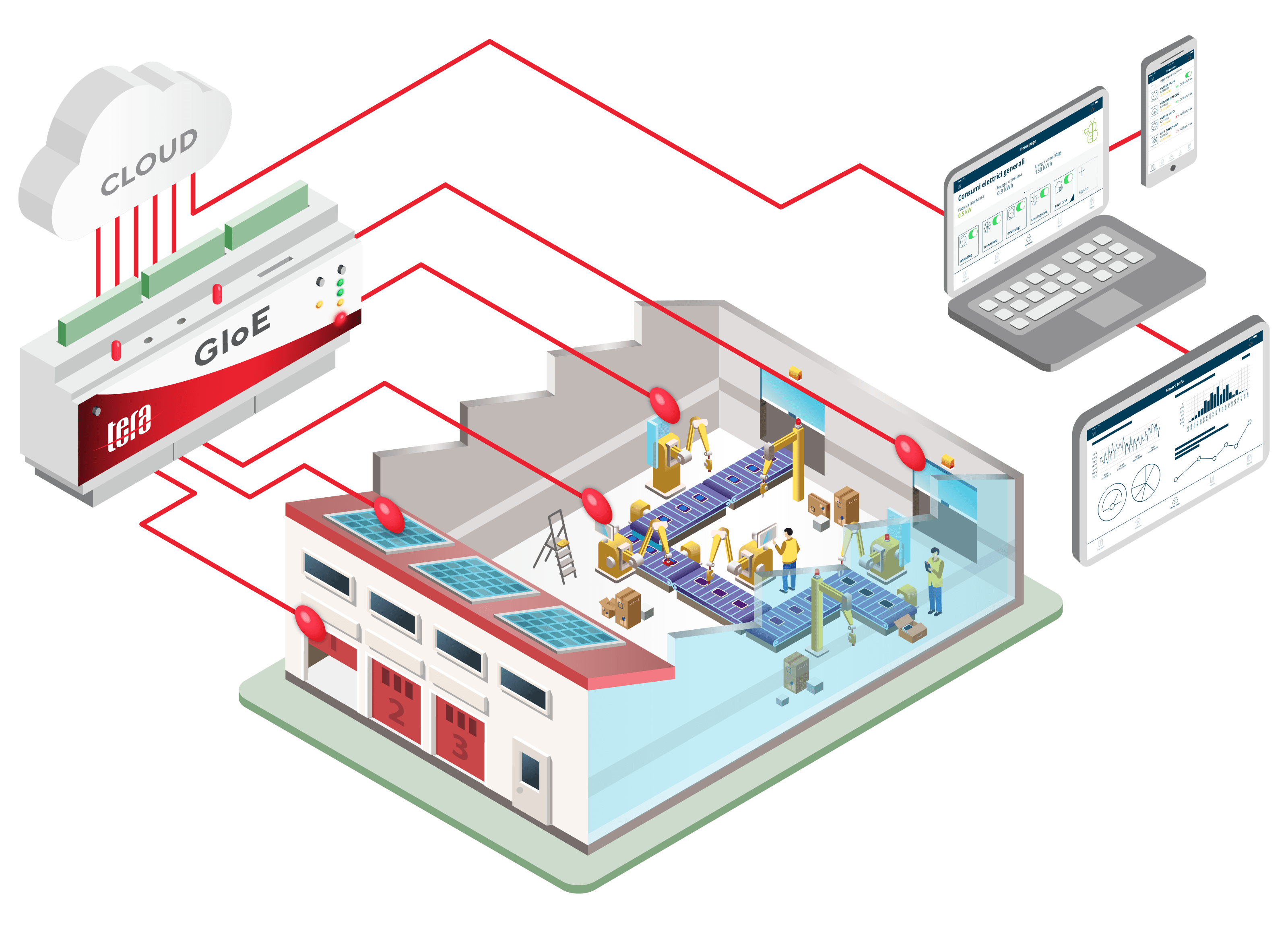

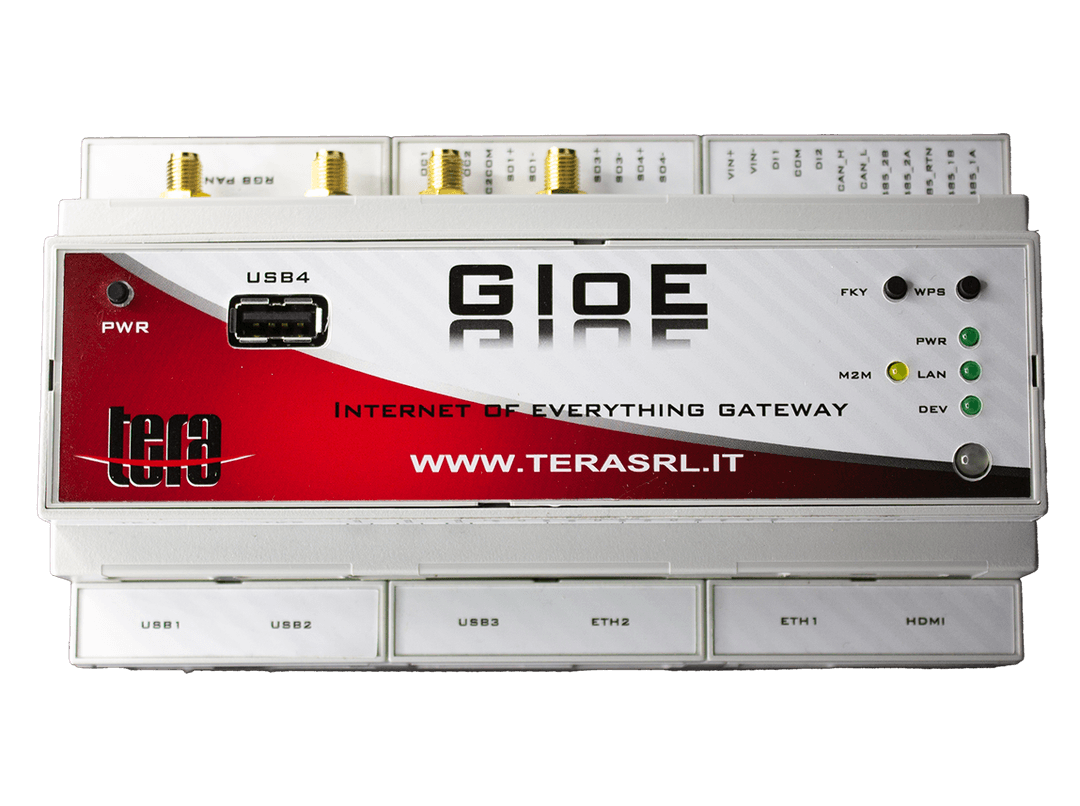

TERA4Industry systems are based on the Smart Gateway GIoE (Gateway for Internet of Everything), designed specifically for the industrial sector, which through the most popular IoT protocols allows communication with various types of devices (sensors / meters / detectors / actuators of different manufacturers and different protocols: vendor-lock-in free approach) and sending data to the Tera4Industry portal.

GIoE: the control unit for the Smart Industry

MoCo: The most compact IoT Edge Computer of the world

GIoE connectable devices allow you to measure:

Consumptions

We carefully monitor energy consumption and production in various areas: from the production line to lighting, from individual machinery to thermal energy. We analyze the consumption of thermal machines, photovoltaic systems, and the energy flow in fluid systems. Our goal is to optimize efficiency and reduce costs, ensuring a conscious use of energy resources.

Processes

We monitor various environmental parameters such as temperature, humidity, brightness, and air quality to ensure optimal working conditions. Additionally, we control the temperature on machinery and production lines, manage gas/liquid pressures, and monitor the force and liquid levels. Finally, we track the number of pieces produced and rejected to ensure quality and production efficiency.

Environment

We monitor soil moisture, water potential, leaf wetness, and meteorological conditions such as wind direction and speed, precipitation, solar radiation, and atmospheric pressure. These data are crucial for managing irrigation, plant health, and understanding the surrounding climatic conditions.

Technologies and production environments always under control.

Real time monitoring.

Predictive maintenance.

Benchmark between production lines.

Optimization of energy resources management.

Incorporation of information with flows managed by existing information systems.

Analysis, Business Intelligence, KPI functions available on Tera software or by integration of opensource tools and third-party platforms:

Consumption for each machine

consumption according to the temperatures detected on the machinery and / or the air temperatures in the work area

Productivity depending on temperature (impact of comfort on the operator) and consumption of the radiant element / air conditioner / thermal machine

Consumption per hour of operator work

Self-consumption and convenience index in adopting an electrical storage system (batteries) for photovoltaic prosumers

KPI for tariff convenience

Typical KPIs for managing only the building (office area)

KPis of specific interest for each process

Tera applications. IoT for energy efficiency

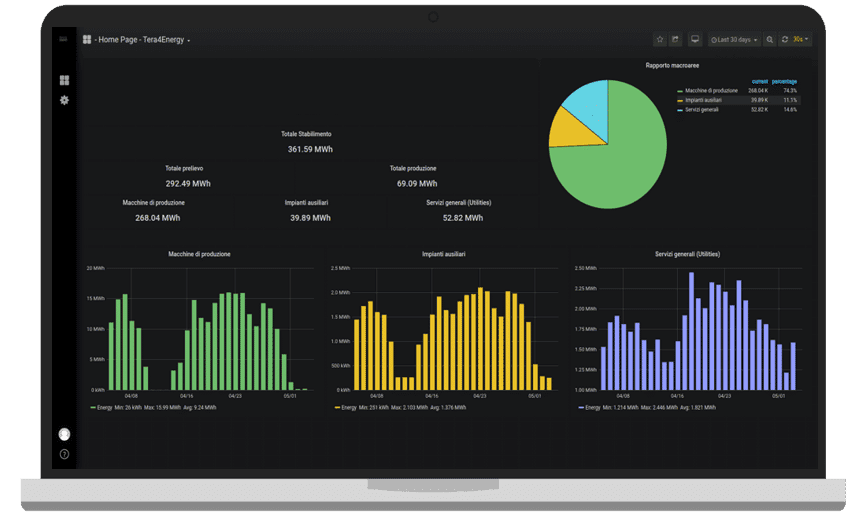

Tera 4 Energy

Tera4Energy implements energy monitoring, enabling a path towards energy and production efficiency for the company, while ensuring compliance with Legislative Decree 102/2014. The system involves installing an interoperable Edge Computer with both wireless and wired sensors that collects real-time consumption data. This information is sent to the Tera4Energy software platform (installable on both Server and Cloud), which displays real-time energy consumption information, triggers alerts for threshold exceedances, and stores and makes these data available for customizable further analysis. The dashboard is user-friendly, providing a synoptic view of consumption trends and total production and consumption values, categorized by function, individual department, or building. It extends to the detailed level of each individual machine or energy load, customizable according to the user's needs.